The coating is a very important part of the overall quality and appearance of the food you make because it affects the texture and taste of the finished product. The way the finished product looks is a big part of how customers decide what to buy.

Late in the 1930s, seasoned breading was used for the first time in a commercial application of the food coating method. This method was particularly popular for use with seafood. Coatings are applied to a wide variety of foods in today’s market in order to boost their value.

Commercial coatings are made up of a wide variety of flours, spices, batters, and breading agents. Together, these ingredients give the product a better look, texture, and color, and they also stop unwanted or outside flavor and moisture from getting in.

Mechanisms involved in the coating process

The majority of the energy required for the process comes from mechanical sources. Most of the time, the process involves moving the product particles in a certain direction while at the same time applying the coating element in a certain way so that the two can come into contact with one another. Adhesion, friction, viscosity, surface tension, and crystallization processes are all involved in this phenomenon.

In a coating system, the coating is applied to the product in several steps, which are sometimes called phases. A dry phase and a wet phase make up what is known as a pass. This is also done to improve the overall appearance or to give the finished product a particular flavor, look, or mouthfeel.

The function of the coating process

The flavor, texture, and weight of food products, including chicken, cattle, fish, pork, shrimp, and other shellfish, may all be improved by coating them. In addition to this, it protects the food from any damage that may occur while it is frozen.

The food items may still look good, but the coating will make them look even better. There are many distinct varieties of coatings, each of which may be made up of liquid components, dry components, or a combination of the two types.

Applications of coating machines

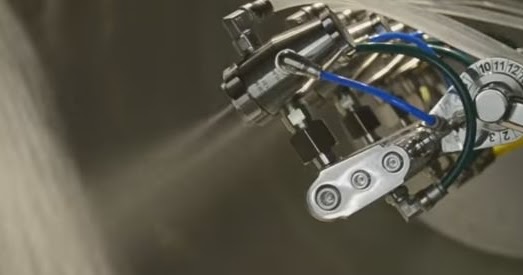

Food items can have measured amounts of liquid or dry components applied to them by using equipment called coating machines. Coatings can be made of batter, breadcrumbs, marinade, tempura, or spices that are applied as powdered seasonings, oil- and water-based coatings, chocolate, yogurt, and other release agents.

Other coatings can consist of chocolate, yogurt, and chocolate-flavored release agents. These coatings are designed to improve the efficiency as well as the quality of the processes and products that they are applied.

Your food products will have a higher value if they have the best coating. To keep up with the movement toward healthier eating habits and lower overall fat intake, coating qualities need to be controlled with more precision.

Are you looking to buy one or sell your coating machine? Our industrial food coating solutions give you this kind of control, and they also give you the ability to make a wide range of tasty foods in a cost-effective way.

With the pre-dusting, battering, and breading equipment that we offer, you can make a wide range of delicious dishes quickly and on a budget.